What is GPR

Ground Penetrating Radar – A geophysical method used to investigate the sub-surface or medium it is applied to. It uses high-frequency electromagnetic waves in the UHF/VHF frequency range of the radio spectrum. These high-frequency signals are transmitted from the system into the ground or medium and the return or reflected signal is received and then displayed back to the operator via the system computer.

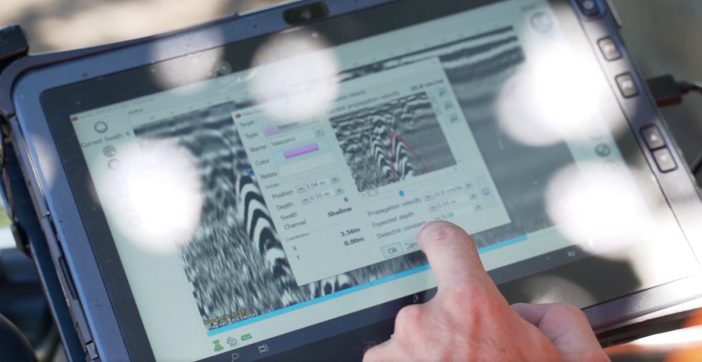

Ground Penetrating Radar, put simply, is a technology that sends pulses of energy into the ground and then measures the reflected signals coming back to the equipment. This provides a complete picture of what’s going on underground including location, depth, and dimensions of objects. The onboard tablet provides a real-time visual indication of underground objects, ground layers, and densities.

When working in the field you can see a graphic visualisation of the data, tag positions with unique markers, and use the grid overlay tool to determine the distance between swaths. There is also the option to overlay Google maps in satellite or road view [wifi dependent].

Why do we use GPR?

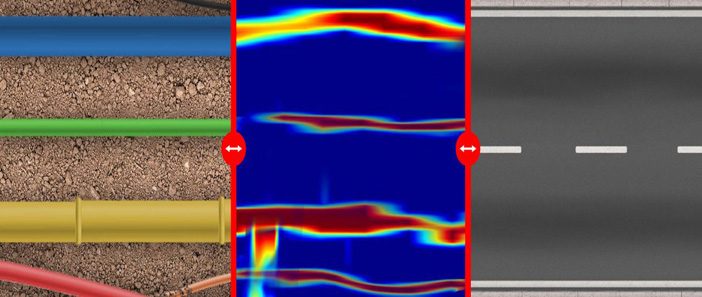

Ground-penetrating radar provides roading, earthworks, concrete contractors, and council developers/asset managers the ability to quickly analyse underground objects across large areas.

- GPR can see beneath asphalt, concrete, soil, sand, grass, gravel, and almost all surface types.

- Risks can then be identified and minimised before earthworks begin, greatly improving safety on site.

Ground Penetrating Radar enables you to locate underground objects including non-conductive pipes and fibre optics. The limitation of other detection tools, such as cable locators, is they can only detect metallic or conductive objects.

How does it work?

Ground penetrating radar sends a signal from a receiver into a surface. The signal is bounced off any materials it encounters within the surface and creates a reading. This reading can then be interpreted by experienced GPR technicians to determine what type of material has been located. Over the years the equipment has become far more user friendly and operating software has become much simpler to use with even expert or simple utility modes. Data can be collected today by less experienced operators and then passed on for interpretation to an expert back at base. Systems today are highly portable offering a utility locating cart-based system that can access almost all areas.

All GPR equipment follows the same basic principles of operation and are bound by the same physical laws.

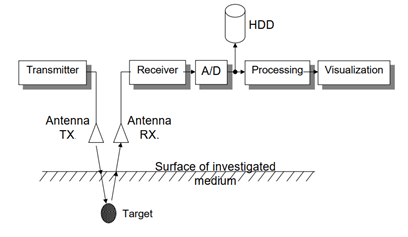

- The radar unit transmits a pulse of electromagnetic energy into the ground or medium being investigated through an antenna transmitter (TX).

- The electromagnetic energy reflected from any target, layer or object detected is recorded by the receiving antenna (RX).

The received signal contains information regarding position and depth relative to the transmit point. The time delay between send and receive signals is dependent on subsurface conditions which affect the velocity propagation of the electromagnetic energy wave

The penetration depth of any electromagnetic signal and its resolution depends on antenna frequency, the power of the electromagnetic wave transmitter, and the electrical properties of the ground it is transmitted into.

Transmitter

IDS system signal flow chart

The signals transmitted from the GPR can be reflected and/or refracted in their path to and from the antenna through their respective transmit and receive phases. A target could be a change in sub-surface layer, buried pipes, cables, voids, in fact anything below ground that contrasts electrically with the host medium and works with the GPR signal to promote two-way travel time.

What does working with the signal mean?

GPR is a geophysical technique so becomes bound by the laws of geophysics, which dictate whether the GPR signal will do to produce the desired result. GPR energy responds to different materials in different ways and the way it responds is controlled by two physical properties of the host material.

Electrical Conductivity

GPR emits electromagnetic pulses of energy and, as such, it is vulnerable to attenuation of the signal as it travels through the host medium (loss of signal through natural signal absorption). A low conductivity material, such as dry sand, will have a high resistive value (inverse of conductivity) and as it travels through the host, the signal does not decay and remains intact for a greater period and consequently has the ability to penetrate the host material to a greater depth.

On the other side, if the host is more conductive (less resistive), such as wet sand, the signal decays rapidly and is absorbed quickly before achieving good penetration depths. Signal attenuation affects how deep we can ‘see’ with the GPR and is heavily influenced by electrical conductivity.

Dielectric Constant also commonly referred to as Relative Dielectric Permittivity

A positive numerical value (=>1) assigned to a material that expresses the host’s properties in relation to (among other things) the speed of which the GPR energy travels through it.

| The GPR signal will always travel as quickly as it can through a material, but some materials will slow the energy more than others.

Table of relative dielectric permitivity (eR), electrical conductivity (σ), and velocity. |

|||

| Material | eR | σ σ (mSiemens/m) | V avg (m/ns) |

| Air | 1 | 0 | .3 |

| Distilled water | 80 | 0.01 | 0.033 |

| Fresh water | 80 | 0.5 | 0.033 |

| Sea water | 80 | 3000 | 0.01 |

| Dry sand | 3-5 | 0.01 | 0.15 |

| Saturated sand | 20-50 | 0.1-1.0 | 0.06 |

| Limestone | 4-8 | 0.5-2.0 | 0.12 |

| Shales | 5-15 | 1-100 | 0.09 |

| Silts | 5-30 | 1-100 | 0.07 |

| Clays | 5-40 | 2-1000 | 0.06 |

| Granite | 4-6 | 0.01-1.0 | 0.13 |

| Dry salt | 5-6 | 0.01-1.0 | 0.13 |

| Ice | 3-4 | 0.01 | 0.16 |

The table above collates some typical materials and their respective relative values. Conductivity is the most influential parameter. Notice how “water” has both the highest and lowest conductivity – and hence attenuation rate – depending upon salinity. The three water types have the same dielectric value of 80, but all have different conductivity values. This conductivity variation affects signal propagation, wavelength and thus penetration. Therefore, it must be recognised that the presence and composition of water is the single most significant contributor to GPR performance. Clay content within the host material is also a very important factor to consider, with only a small amount of clay contributing to a potential significant decrease in GPR performance.

Taken in isolation, the Dielectric Constant can be confusing as a value. Distilled water and sea water both have a dielectric constant of 80 but have very different conductivity rates and velocity speeds which will produce different results.

The use of a simple numerical value can help us in assessing the system performance almost immediately as we scan the host material. For us to ‘see’ the reflection produced there must exist a contrast in dielectric value of the host material and the target. The reflection is produced at a boundary between the two contrasting materials where there is a sudden change in both the dielectric and signal velocity, the greater this dielectric contrast or difference between the materials, the stronger the reflection. Furthermore, the contrast between the host material and the targets respective electrical conductivity will affect the brightness of the reflection. A metallic target which is conductive will produce a strong reflection due to the massive contrast between it and the host material as it reflects the energy back, it will also have an extra signal present where the target has become charged, whereas a non-conductive target such as plastic will return reflected energy only.

One important fact is that because a metal target is a complete reflector of GPR energy, then too much metal in a scan will detract from the overall effectiveness of the system. Aluminium foil will totally reflect all the energy back from itself and would be a bright reflection, anything below would remain invisible. Rebar when tightly meshed scatters the GPR energy from its original path making scanning difficult, buried wire mesh (5cm x 5cm) would potentially be impenetrable.

The Leica DS2000 GPR

Leica DS2000 GPR features a dual frequency antenna which enables you to simultaneously detect shallow and deep targets providing a more advanced profile of underground objects. With a rugged design and advanced ergonomics, the Leica DS2000 GPR is designed specifically to easily manoeuvre around worksites, even those with challenging terrain or uneven surfaces such as gravel, rock, soil and ice.

The Leica DS2000 GPR can operate with or without the optional RTK GPS (for mapping applications). Simple intuitive software and data that is stored on the tablet make this solution easy to use with no need for post-processing.

The Leica DSX

The Leica DSX – an all in one utility detection system designed for less-experienced and first time ground penetrating radar [GPR] users.

It is a highly advanced yet easy-to-use solution for locating and mapping buried utilities in a safe, fast, and reliable way, without the costs of hiring a specialist. Investing in the Leica DSX will also save on potential damage costs, cost of utility surveying, downtime of damages, and training.

Unlike other utility GPR systems, the DSX automates data analysis and creates a 3D utility map in the field, streamlining workflows and maximising onsite efficiency.

The integrated DXplore software simplifies the process by taking away the complexity of data processing, reducing the amount of time required to post-process in the office as well as allowing detection to be easily performed and validated by new GPR users.

Not only does the Leica DSX reduce the costs and time involved with utility mapping, it also delivers improved accuracy due to the best-in-class positioning accuracy from Leica Geosystems devices, reducing safety risks even further.

Its robust and portable design means that it can be easily taken on-site and used to scan anywhere and at any time, even in narrow areas and under harsh conditions.

C-Thrue Concrete Scanner

Knowing what lies behind concrete before cutting or drilling improves safety and safeguards against the risk of damage. The C-thrue concrete scanner is a handheld GPR system that can be used for Non-Destructive Testing, concrete inspections, structural analysis, bridge deck analysis, in fact anything, when you want to perform high resolution shallow investigations.

Featuring 4 antennas scanning in horizontal and vertical polarisations, the C-Thrue concrete scanner is capable of scanning through concrete up to a depth of 80cm. The dual antenna polarisation delivers visualisations that accurately show optimal detection of both first and deeper levels of rebars

C-thrue offers more flexibility with no limitations for your analysis requirements, thanks to a compact and light telescopic pole and an external controller that can be easily transported on site in challenging locations or conditions (e.g. under a deck, along vertical walls, etc.). The C-thrue external controller allows easier and faster data interpretation thanks to real-time data processing and representation of results in Augmented Reality for more efficient decision-making.

Stream C

This system uses 32 antennas in one array housing, it has a big footprint, and it also uses antennas with two polarisations. Of the 32 antennas, nine are horizontal (HH), 23 are vertical (VV), and are spaced close together. The consequence of this is that The Stream – C can collect and process scan data and assemble it live in a 3D format, yes live 3D mapping. It has a central frequency of 600mhz across the array, so ground conditions dependent, 2.5 metres can be achieved with excellent results. It can even be towed behind a vehicle; if that’s not your thing, then there is motor assistance depending on the model chosen

If you are interested in learning more about our range of GPR solutions and the capabilities of scanning technology, talk to our team of technical specialists. We’ll be able to suggest a solution that is right for your requirements and includes training, servicing and industry leading after-sales support.