“Boom times, skilled labour shortages, higher job complexity and ever-increasing client expectations have meant the civil construction industry is increasingly looking toward technology to improve productivity, solve skills and resource issues and improve profitability.”

INTERNATIONAL STUDIES, such as the McKinsey Global Institute Industry Digitisation Index, show that the construction industry has one of the lowest rates of technology implementation and sits well behind industries like mining and manufacturing – ranking 15 out of 16.

The opportunity exists for significant gains in productivity and efficiency via the adoption of technology and through digitisation of construction processes.

Traditionally construction has been very much a manual process whereby projects are surveyed, designed and then paper plans generated for construction. Talk to any contractor and they will tell you horror stories of incomplete plans, design errors, misinterpretations and costly rework which the contractor often ends up having to cover. Given that all design is done digitally nowadays the current manual construction process is inefficient, costly and carries high risks for the contractor – especially when errors are not discovered until part way through construction.

Taking a higher level overview of this process, many of the issues that are regularly seen can be mitigated or eliminated through digitisation and empowering people onsite. The engineering and construction industries have made significant progress in the past 10 years with digital design, however we are only at the beginning of a journey which will, in our lifetimes, radically change the way our industry operates.

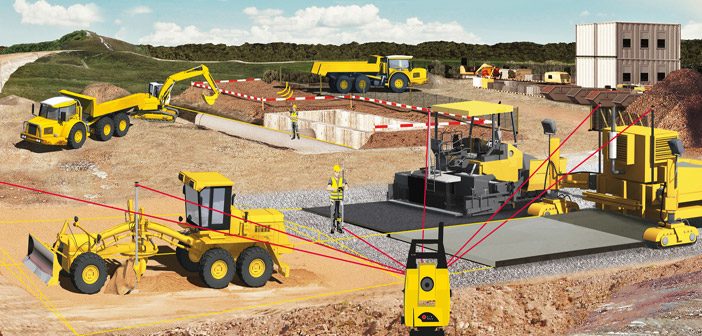

Globally the divide continues to widen between constructing using traditional techniques (2D plans) and constructing via technology using and machine control systems. Each year the technology advances further, becomes more powerful, generates higher levels of productivity and is easier to implement for business managers and staff, as well as being more affordable in terms of its return on investment.

The construction industry is following global trends with the rapid adoption of machine control technology.

“Whether used for bulk earthworks or final pavement layers, virtually all major capital projects employ some form of machine control technology today as a core part of their construction methodology.”

The tight tolerances on many of these projects necessitate the use of machine control as it’s simply not possible to meet the requirements without it.

On smaller projects, where the tolerances aren’t generally as tight, the productivity benefits, savings through minimising rework and ability to self-manage the construction process are the main drivers behind the rapid adoption of the technology.

Within the construction industry most business owners list a lack of skilled staff in their top three current business challenges. Increasingly contractors are looking toward technology to help solve some of those challenges. Younger people entering the industry have grown up in a digital world and easily embrace new technology and working in a digital environment.

Companies embracing a digital construction process are able to take lesser skilled operators and make them highly productive in a short period of time and therefore gain a competitive advantage. This is a way of not only coping with labour and skills shortages but can also assist with retention of key staff and providing career development and opportunity.

Working Smarter

The construction industry has also become smarter in the use of GPS rovers, robotics and drones, which enable the contractor to easily quantify their work on measure and value contracts to ensure they get paid for the work completed. By moving to a digital process the contractor doesn’t have to rely on an often inaccurate schedule of quantities or load counts.

Tools are now readily available for contractors to manage all their set-out, as-builts, volumes and quantities on projects with full reporting in the field. This allows contractors to manage the entire project and make decisions without being reliant on external surveyors and engineers.

At the same time design software has evolved significantly over the past 15 years making the production of 3D models a relatively easy task. Whilst the use of 3D models and machine control technology is now commonplace in New Zealand there are benefits to all parties (clients, designers and contractors) through full digitisation which are not yet being fully realised.

The client and contractor stand to benefit the most in moving to a digital workflow as contractors are able to deliver projects more cost effectively, to higher construction tolerances and quality in a shorter timeframe.

The industry would benefit further if 3D models and designs became integral parts of the contract documentation for use by the contractor. This adds a higher level of accountability on the designers to ensure their design is correct which should be the ultimate goal of any efficient industry.

This digital construction process is well established internationally with machine control and construction survey technology a prerequisite on most major projects. Whilst it’s not mandated in New Zealand, it’s commonplace and those trends will continue.

For people working in the construction industry this shift in the way we construct brings with it exciting opportunities. Our industry is often not seen as the most exciting choice for younger people despite the excellent career and opportunities.

The trend toward digitisation allows people to put themselves at the cutting edge of the industry and keep up with the latest developments in technology. I truly believe it is something we, as an industry, should be actively promoting when trying to attract younger people into construction.

Looking Into The Future

I expect the technology to develop further around measuring plant efficiency and productivity to optimise the best use of both plant and resources. Similar industries overseas, such as mining, are significantly further ahead than construction on the technology curve and are reaping the rewards. It is commonplace for mine sites to quantify machine downtime, dynamically reschedule the use of machinery in the event of breakdown and optimise haul-times etc to ensure the mine site is working at its optimum.

In building construction, BIM (Building information Modelling) is re-shaping the way we construct and maintain buildings and facilities. Like building construction, the civil construction process is complex with decisions being made on a daily, if not hourly, basis which can affect the construction process.

The BIM process empowers people onsite by putting information and decision-making tools in their hands. Many of the learnings from the BIM process are transferable into civil construction and as the digitisation of the industry accelerates we can expect to see the way we construct and manage assets evolve with it.

Looking further ahead into the future, and on a larger scale, we are seeing the concept of digital cities evolve with CIM (City Information Modelling). CIM is a process whereby every asset above and below ground is precisely mapped and attributed including all the structures, material types, services etc and can then be used by a wide range of industries including construction, facilities management, emergency services, planning and design, etc.

In a challenging labour market, contractors are increasingly looking to use technology to increase productivity, resolve skills and resources issues and gain a competitive edge. In the digital world we now live in, there is significant scope for our industry to benefit and gain efficiencies through the digitisation of our construction processes.

We find ourselves in exciting times, on the brink of realising significant change in the way the industry constructs and delivers projects through digitisation.

|

Ray Copeland is Managing Director of Global Survey New Zealand.

Instrumental in introducing the first 3D grader control system into New Zealand in 2001, Ray has extensive knowledge and over 20 years of practical experience in GNSS surveying and machine control technology in both the survey and civil construction industries. Connect with Ray Copeland on LinkedIn or email ray@globalsurvey.co.nz |

Reference: McKinsey Global Institute Industry Digitisation Index Report 2015.

[This article first appeared in NZ Contractor Magazine Perspectives 2018] SHARE THIS ARTICLE