The Watercare Central Interceptor Project in Auckland has reached an exciting stage as the team prepare for the arrival of Hiwa-i-te-Rangi their giant new Tunnel Boring Machine [TBM] which is currently being built in Germany.

The main contractor Ghella Abergeldie Joint Venture are building the Central Interceptor over six years with most of the construction work taking place underground. The 190m long TBM will be used to bore through the earth’s substrate and lay segments of the tunnel as it goes.

[Photo: May Rd Shaft A excavation underway – 20 Aug 2020]

Visible above-ground construction will be contained to the 17 sites where vertical shafts will be built and connections made to local sewer networks and overflow points.

The first two shafts at Māngere and May Rd shaft A are already well under construction. The Māngere shaft will be 40m deep with a diaphragm wall that will extend -50 to -54m underground to create the deepest diaphragm wall in New Zealand history. While May Rd shaft A will be a smaller diameter but some 67m deep, the lower 40m will be shotcrete lined to stabilise the walls.

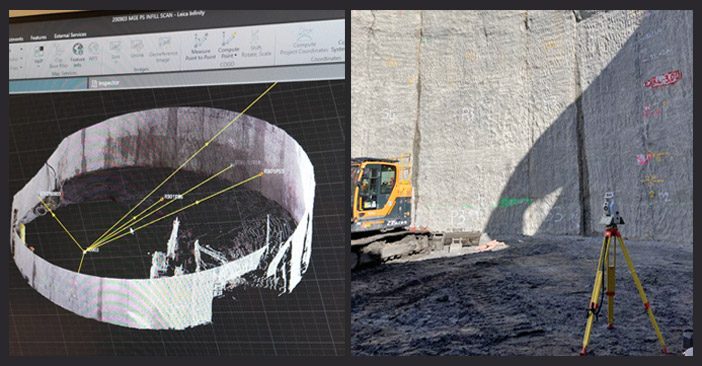

[Photo: Band scan point cloud data from May Rd vertical shaft captured by the Leica MS60 displayed in Leica Infinity office software]

Comparing Surfaces of Scanned Structures

The Ghella Abergeldie Survey Team are equipped with the latest Leica Geosystems technology including the new model Leica MS60 MultiStation, a powerful robotic total station with scanning capability. One of the unique features of the new Leica MS60 is the Inspect Surfaces App which is proving popular with Surveyors around the world as a valuable tool to compare the surfaces of scanned features.

First the survey team position the Leica MS60 at the bottom of the vertical shaft using the Leica Captivate Resection Sets App. Then they use the Inspect Surfaces App to compare the scan with the shaft design using a “heat map” which shows inconsistencies between the design and the real structures.

This enables the Surveyors to communicate directly with the Construction team onsite and in real-time so that surface inconsistencies are immediately identified.

|

“The Inspect Surfaces App was just what we were looking for. The ability to directly compare reality with design in the field is of huge benefit. The Leica MS60 is our “go to” instrument and we are looking forward to using it on different stages of the tunneling project.”

Les Whalley – Mine Surveyor, Central Interceptor Project |

The Ghella Abergeldie Survey Team have also taken delivery of several Leica Robotic Total Stations, Digital Levels with invar staffs and Controllers with the advantage that data is captured in Leica Captivate across all instruments. Leica Infinity office software enables data sets to be combined and processed and for QA checks to be completed.

As this project progresses, Bryan Claridge and the wider Survey Team at Global Survey will be alongside to provide ongoing technical support and assistance.

A Long-Term Strategic Infrastructure Project

There is no doubt that the Central Interceptor Project is a crucially important project for Auckland and one of the largest ever undertaken. It is specifically designed by Watercare to deliver better and more effective wastewater management within the Auckland region and to provide for future growth.

Historically older storm water pipes have been overwhelmed in heavy rain and overflowed into the city’s natural waterways. Over six years the Central Interceptor tunnel will be built to help make Auckland’s waterways cleaner.

The Central Interceptor tunnel will run underground from Grey Lynn to the Māngere Wastewater Treatment Plant. It will have several linked sewers and shafts along the route for collecting and transferring wastewater into the tunnel and once complete will be 14.7 kilometers in length, the longest wastewater tunnel in New Zealand history.

Ghella Abergeldie has more than 150 years’ experience with tunneling and wastewater projects of this size across the globe.

Find out more about the Central Interceptor Project

Talk to our Survey Team about the challenges of your next project.

SHARE THIS ARTICLE